F O Engineering has a strong background in designing and developing products and systems for the Aerospace industry. Products range from simple analog electromechanical actuator controls to high performance, redundant digital based system controls. All products are designed to withstand the harsh environments typical of Aerospace ground and flight applications, such as temperature, vibration, power conditions, EMI/EMC, etc.

F O Engineering’s extensive experience in system design and control electronics allows a one-stop-shop for electromechanical systems from concept through design, integration and production. Whether it’s a self-contained miniature motor controller or a large and complex system design, F O Engineering can help solve your problems.

Defense

Defense product design is driven by high performance in small packages. F O Engineering’s successful defense products incorporate high performance digital designs that occupy very small volumes, and are usually incorporated into the actuator itself, further reducing actuation system volume and enhancing overall system performance. Integration of the control electronics into the actuator housing allows F O Engineering’s system knowledge and expertise to ensure the success of the product, quickly identifying and correcting system issues as they arise.

Programs

Programs

5-GAT 5th Generation Aerial Target

F O Engineering (FOE), Inc. was selected by the 5GAT prime contractor, Sierra Technical Services (STS), Inc. to provide complete subsystem design solutions for the 5th Generation Aerial Target (5GAT) Drone air vehicle. 5GAT is a “Threat Representative,” “Low Observable” full-scale aircraft adversary, US Warfighters may encounter in an aerial combat situation. As a high-performance, unmanned, fighter-sized aircraft, 5GAT will be used for Air-To-Air and Ground-To-Air weapons evaluation, pilot training, and ground forces training. The FOE-responsible subsystems applications are as follows for the 5GAT air vehicle: - Design Authority

• Flight Control Actuation

• Hydraulics

• Fuel

• Electrical Power

• Landing Gear

• Steering

• Braking and Antiskid

• Tail Hook and Arresting Gear

• Secondary Utility Actuation (i.e. Propulsion Cooling Bay Vent Doors)

• Aircraft Cabling and Harnessing

F-22 Canopy Actuator Control

-

Build to print Canopy Actuator Control.

-

Identified and replace obsolete parts.

-

Re-engineered, designed and fabricated test equipment to meet original OEM requirements.

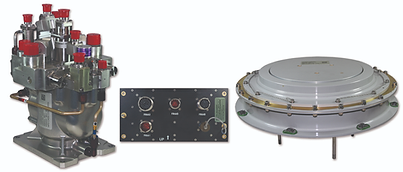

KC-46A Hydraulic Hose Reel Drive System

Drive System Controller (DSC)

-

Design Authority

-

F O Engineering is a primary contributor to Centerline Drogue Refueling System integration

-

All hardware and firmware developed by F O Engineering

-

Flight Qualified equipment to MIL-STD-810 and RTCA DO-160G requirements

-

DO-178B Level B software quality certified

-

The DSC contains all refueling system control laws

-

The DSC communicates to the aircraft via ARINC 429 protocol

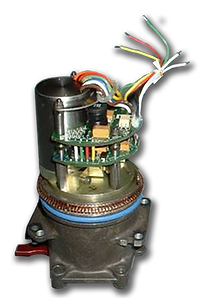

Missile Fin Controls

-

Design Authority

-

Single board design

-

Rapid development

-

Magnetic Hall Effect positioning

-

1 KHz command update rate

-

Cost-effective in-house development

-

Full production at F O Engineering facility

-

Buid-to-Print capabilities

A-160 Hummingbird Control Systems

-

Design Authority

-

Main Rotor Actuator Control (MRA)

-

Tail Rotor Actuator Control

-

Landing Gear Actuator Control

-

No Skid Brake Actuator Control

-

MRA required 50 Hz bandwidth

-

Cooling Fan Controls (Avionics and Engine)

-

Complete actuator integration

-

9 HP in a 7 cu. in. controller

P-8 Poseidon Fuselage Fuel Dump Valve

-

Design Authority

-

Dual redundant

-

6 per vehicle

-

Currently 12 P-8 Poseidons flying

-

Full digital servo loop

-

Automatic calibration at assembly

-

Onboard EMI filter

KC-135 Trim Air Valve Actuator Controller

-

Design Authority

-

F O Engineering used solid state components to replace mechanical switch and relays for increased reliability

-

Developed software to eliminate mechanical adjustments

-

DC operation with 400Hz AC converter option

-

Flight qualified

-

Success of this program leveraged to a 2 channel active standby redundant design